Mod Details

PremiumNo Difficulty

Mod ID811

Creditevilution

For

Mod ID811

Creditevilution

For Linkhttps://www.evilution.co.uk/mod/450-door-handle-cable-repair.htm Copy to Clipboard

Linkhttps://www.evilution.co.uk/mod/450-door-handle-cable-repair.htm Copy to ClipboardDue to lack of good and regular maintenance, the 450 door exterior cable tend to snap.

The problem here is that the cable is not available from smart. You have to buy a whole new handle. Or you could buy a 2nd hand handle from eBay and hope the cable is OK.I was contacted by Gerry in the US who said that his had snapped and was having issues getting a cable. So, I bought a 2nd hand handle and told him that I would either reproduce a cable or send him this one.

I already had all of the parts and tools as it’s something I was going to do a long time back.

What If I’m Useless And Just Want To Buy A Cable?

Originally you were shit out of luck as smart didn’t sell them separately. However, no you can buy them from SmartMods. Click here.

What If I’m Awesome And Want To Make A Cable?

Remove the handle from the car.

Flip it over, pull the handle and you’ll see the cable capture point.

Pull/lever the old cable end out.

Look down the top of the white clip. Unhook it…

…and slide the cable mount off of the handle mechanism.

Most people having this problem will have a cable looking like this. Snapped at 1 end.

This type of cable is known as a Bowden cable and is common on bicycles. The existing cable sheath outside diameter is 4mm. You must buy a matching diameter. I bought a Jagwire LEX kit from eBay. This contains 4mm and 5mm cable sheath. You only need the 4mm.

You’ll also get steel inner cables to match. You’ll need the thinner cables (1.2mm).

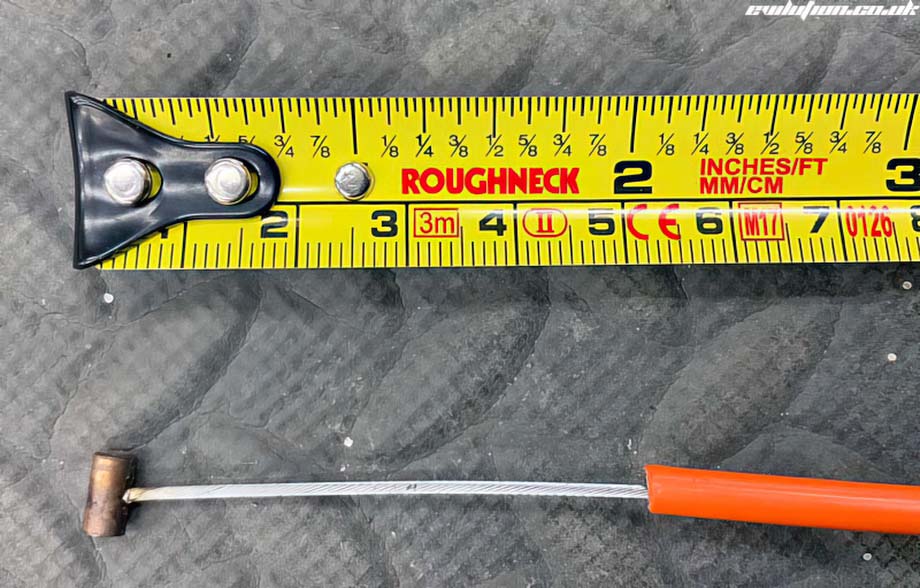

You will need a pipe cutter, cable cutter and a pokey pokey tool. (Other tools required later).

The barrell end is 4mm in diameter…

So you’ll need some 4mm copper tube. Often used for model making. I bought mine from eBay. It has a 0.45mm wall thickness. It cost about £3 for 300mm in length.

The existing cable end is 8mm in length…

…so drill a 1.5mm or 2mm hole into the copper tube. 4mm back from the end.

Measure 8mm back, mark it and cut the piece off.

Make another one as you’ll need one at each end.

Take the new 1.2mm inner cable and flux it to help the solder flow and to clean the wire.

Push it into the hole and use the pokey pokey tool to spread the cable so the end stays in place.

Clamp it in a vice or put it down on concrete.

Heat the copper end with a gas gun and feed solder into the hole until it has filled up. Allow to cool and file back any excess solder if you have any.

Make sure it fits the handle as expected.

Cut the cable down to 26cm (about 10 inches) to make it easier to work with.

Pull the rubber grommet off of the cable mount…

…and pull the old cable from the back. Clean up the hole that it came from.

The existing outter cable is about 165mm long.

Cut a matching length from your new outter sheath.

Use the pokey pokey tool to make sure the hole is ok in the end and not deformed.

Put the rubber grommet over the new inner cable…

Push the new inner cable into the cable mount.

Push your new inner cable into the mount and pop the grommet into position.

It helps to now attach that end to the exterior handle. Now push the other end into position on the door catch. The lever that the cable pulls has a lot of movement before it opens the door.

Mark where the cable touches the lever, cut the cable, flux it, insert the inner cable, splay the cable with the pokey pokey tool and solder as before. Once fitted, the finished cable is connected to the lever, the lever should be under a little bit of tension so the cable doesn’t fall off.

Here is the completed cable that I sent off to Gerry.

When pulled all the way out and not attached to the external handle, the distance from the inside shoulder of the end pin to the beginning of the sheath should be as close to 45mm as possible.